4MX

Products / Plastering, Turbo-S-Line

The Advantages

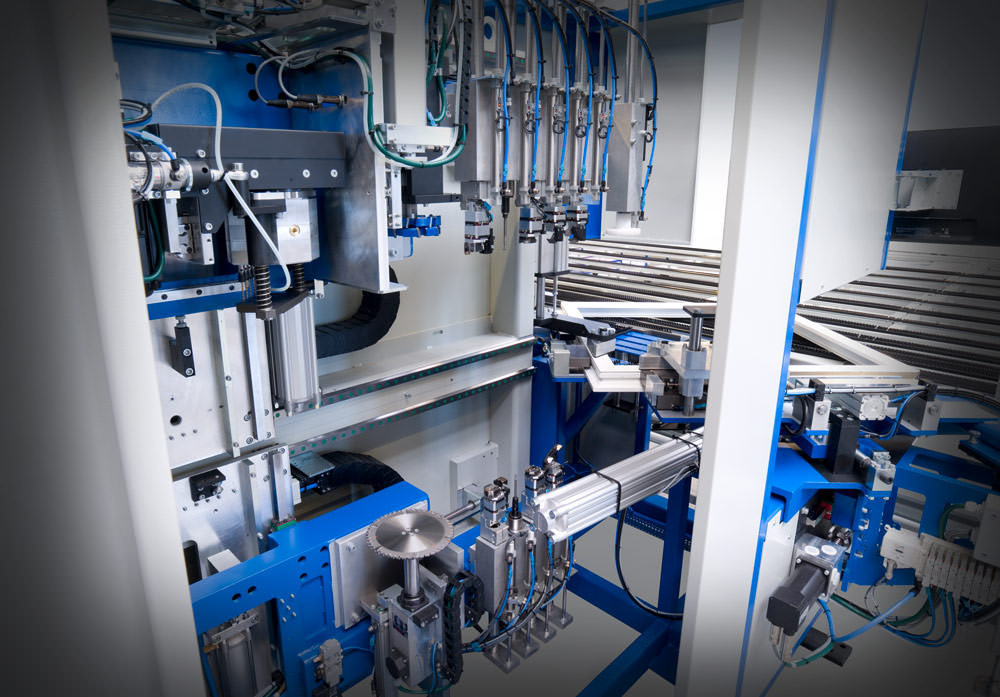

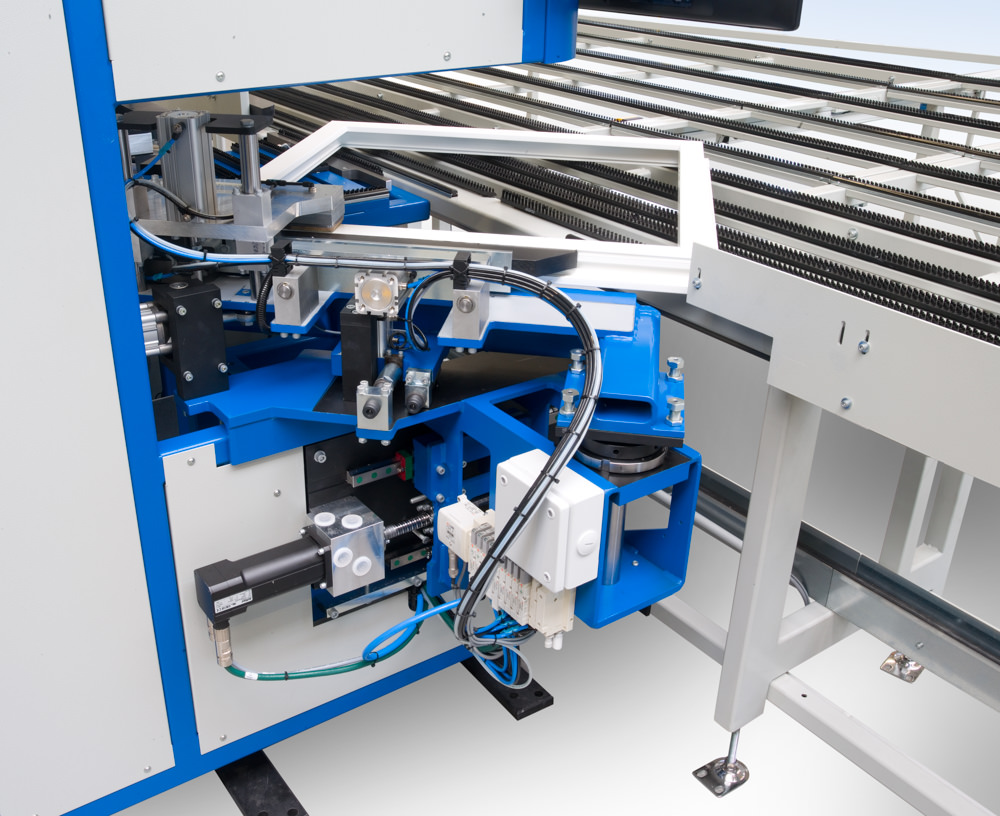

- 4-axis single-head plastering machine

- Highly dynamic drives for short machining cycles

- randomly programmable using a 23 inch touch screen and Windows operating system

- With graphical representation of the profile cross-sections and display of the applicable processing steps

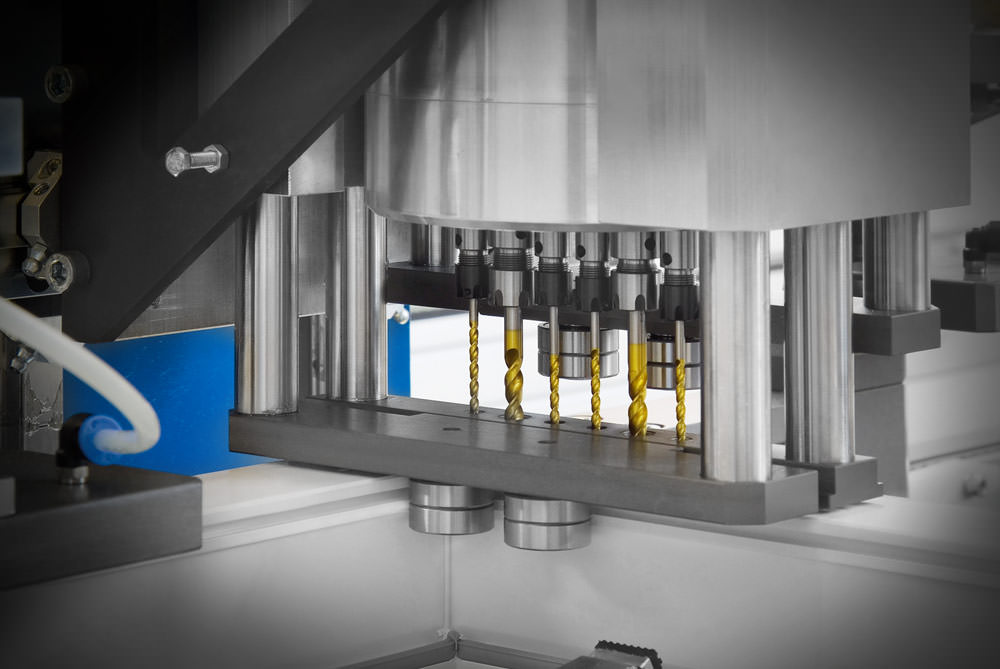

- Tools for the machining of the inside with linear guide technology for highest precision

Standard tooling

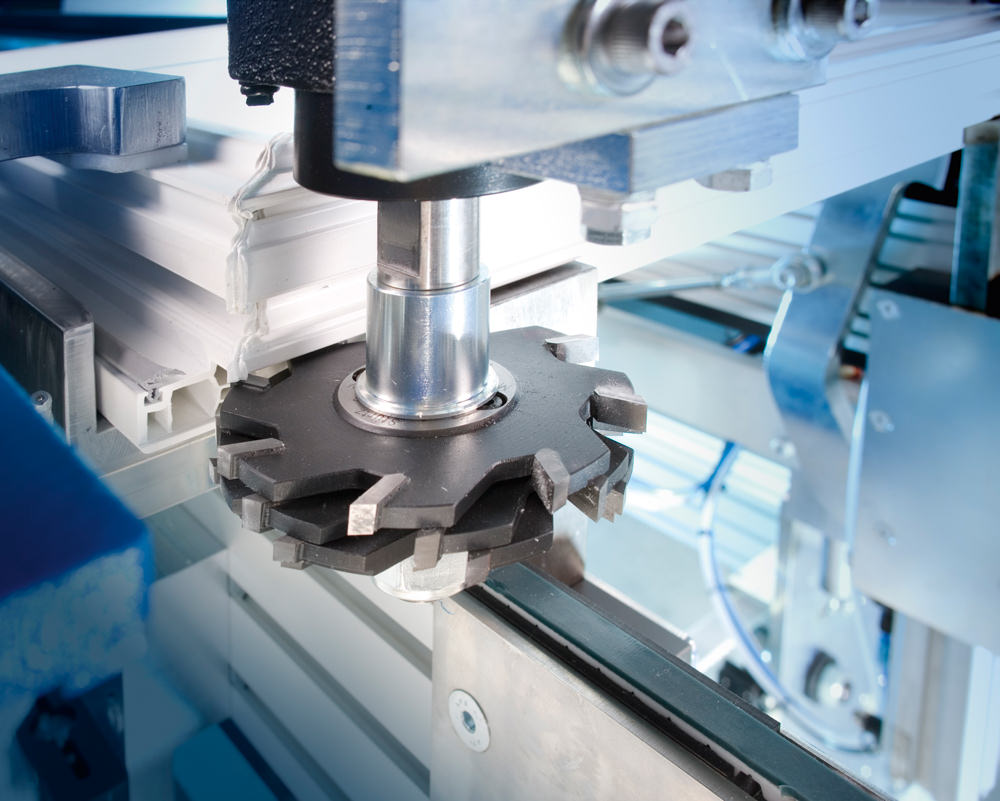

- Upper machining Inner corner and grooving blade (design as V-groove available), 1 bevel unit, drilling motor, exterior contouring sawing disc

- Lower machining: Inner corner and shadow groove blade (design as V-groove available), drill motor

Optional tooling

- Radius machining with KI knife assembly

- Flat cleaning for coloured profiles with FME knife unit possible

- Sliding frame machinable with HIR milling unit

- Disc milling unit SFA

- Pivot post and scissor stay hinge drilling on the frame

- Leaf hinge drilling

- Milling the frame corners (if different frame widths)

- Casement mullion milling

- additional machining upon request

- Integration of a turning station is possible

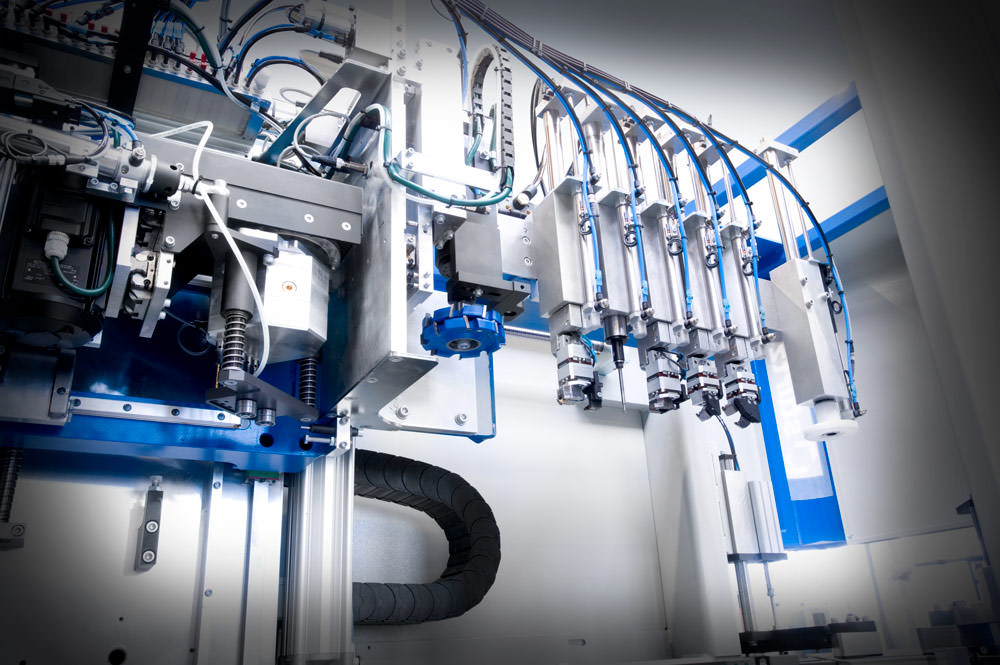

CNC-controlled operation

at the highest quality level

cycle time optimised work sequence

with MotionControl

Modular tooling

up to 17 tooling places

TECHNICAL DATA

Component size min. (clear inside dimension) 190×190 mm (WxH)

Component size max. 3000 x 3000 mm (n reversing operation)

Profilbautiefe min. 25 mm

Profilbautiefe max. 130 mm

Profilansichtsbreite min. 25 mm

Profilansichtsbreite max. 130 mm

PERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.